Dhena

Celia

master of science

in fisheries and marine biotechnology

Experienced in a wide range of industries especially fish processing and aquaculture. Enthusiastic and passionate about creating innovative products by applying biotechnology to enhance the food and aquaculture industry.

Specialized in

- Fish Processing

- Fisheries Bio-products

- Marine Biomaterial

- Fisheries Biotechnology

- Aquaculture Management

education

2023

- Bachelor of Fisheries Science

- in Fisheries Product Technology

- GPA: 3.77/4.00

2024

- Master of Science

- in FIsheries and Marine Biotechnology

- GPA: 3.84/4.00

product Quality Control staff

Aug 2019 - Aug 2020

Fisheries Processing Club at Airlangga University, Fisheries and Marine Faculty

Fish processing into food products

- Performed organoleptic evaluations on raw materials focusing on fish and ensured the quality of final products (Sempol Ikan Lele) prior to consumer distribution.

- Managed quality control measures across all production phases, adhering to established food safety protocols such as HACCP, critical control points, and GMP.

EXPERIENCEs

Aquaculture management intern

Dec 2019 - Jan 2020

CV. Andini Sakti

Whiteleg shrimp (Litopaneus vannamei) aquculture

- Implemented aquaculture strategies to maintain optimal aquatic systems and minimize mortality rates.

- Collected and analyzed data on shrimp growth and health, including water quality monitoring, feed consumption, and mortality rates to support sustainable aquaculture practices and environmental conservation.

EXPERIENCEs

Market research intern

Feb 2020 - Jun 2020

Eawag

Sustainability waste treatment with Black Soldier Fly Larvae (BSFL)

- Utilized targeted B2B outreach strategies to engage with vendors and companies, promoting black soldier fly larvae (BSFL) products and fostering strong business relationships.

- Participated monthly B2B focus group discussions to evaluate product performance and gather insights for product development.

- Analyzed market trends and consumer behavior, collaborating with stakeholders to determine potential demand and inform strategic decisions.

volunteer

May 2021 - Dec 2021

Go Forward

Enviromental sustainability by focusing on waste management

- Collaborated with a multidisciplinary team to develop and implement innovative and sustainable waste management solutions.

- Organized workshops (BSFL-based bioproduct) on environmental sustainability, focusing on waste management and recycling practices.

- Created educational materials and reports delivering impactful presentations to educate and engage the community.

Research Intern

Jan 2022 - Feb 2022

UD. Family Food

Quality control in the production of fish balls

- Implemented quality control processes across production phases to ensure compliance with industry standards and regulations, including HACCP, critical control points, and Good Manufacturing Practices (GMP).

- Maintained regulatory standards and protocols to ensure compliance with relevant regulations and industry guidelines, including fish processing and food safety.

- Utilized software tools for daily operational tasks including data tracking and reporting

EXPERIENCEs

Export Internship

Aug 2021 - Jan 2022

Sekolah Ekspor

Developed a comprehensive export business plan to successfully export water hyacinth handicraft product

- Conducted thorough market research, identifying potential export markets and analyzing competitors to inform business strategies and optimize product offerings.

- Created a detailed export business plan, outlining product offerings, target markets, pricing, and sales projections to ensure the successful launch and growth of the export business.

- Utilized digital marketing techniques to promote products and engage with target audiences, increasing brand visibility and driving sales.

bachelor’s thesis

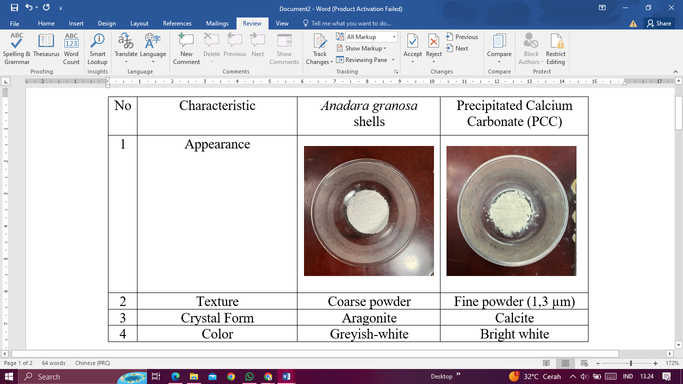

Effect of Precipitated Calcium Carbonate (PCC) Concentration from Blood Clam Shell (Anadara granosa) on Bioplastic Characteristic

research background

Bioplastic production requires raw materials with specific properties, depending on the product's function. Starch, a common bioplastic material, has hydrophilic properties, limiting its application. This limitation can be addressed by adding fillers like calcium carbonate, which can be sourced from blood shellfish by-products. Incorporating calcium carbonate from blood mussel shells improves the physical properties of corn starch-based bioplastics.

objective

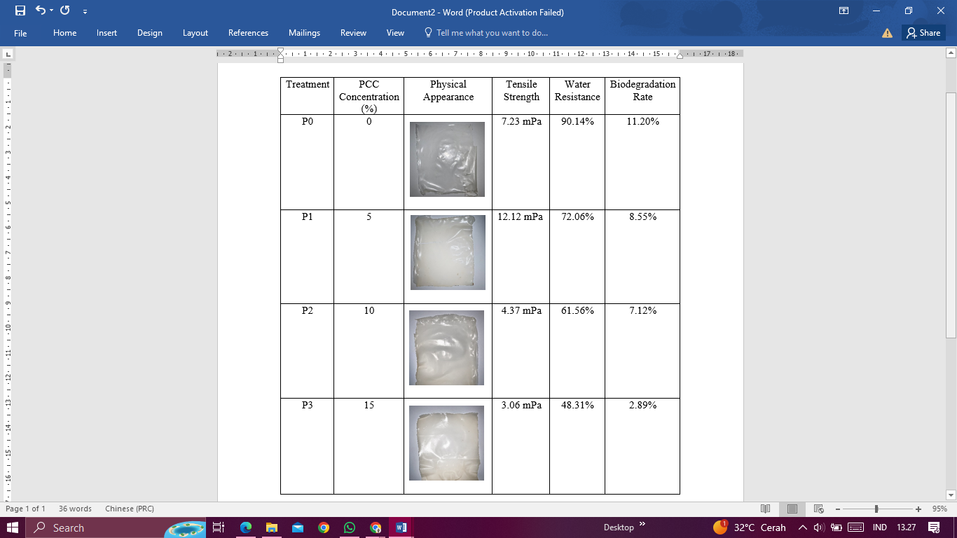

The purpose of this study was to determine the effect of the concentration of PCC filler (0%, 5%, 10%, 15%) from Anadara granosa shells on the physical properties of bioplastics.

Method

PCC was created through purification from Anadara granosa shell, calcination at 800°C for 4 hours, washing with 2 M HCl 37% in 100ml and 1 M NaOH in 100ml. The resulting PCC was analyzed using XRD and PSA. Production of corn starch-based bioplastics was added with PCC concentrations of 0%, 5%, 10%, and 15%. The bioplastics were then evaluated for tensile strength, swelling test, biodegradation rate and compared to JIS. The data was analyzed using ANOVA at the 5% significance level, followed by DMRT at the same level.

result

discussion

The best tensile strength results were obtained from bioplastics with a PCC concentration of 5% which is 12,121 mPa which is in accordance with the Japanese Industrial Standard (JIS). The best water resistance results were obtained from the bioplastic swelling test with a PCC concentration of 15%, which is 48.306%. The results of the biodegradation ability show that the higher the concentration of PCC to which bioplastics are added, the longer the rate of bioplastic degradation.

conclusion

Based on these results, it shows that there is an influence of the concentration of Precipitated Calcium Carbonate (PCC) filler from blood clam shells on the physical properties of bioplastics which include tensile strength, water resistance, and biodegradation ability.

Scanning Electron Microscope (SEM) of kappa carrageenan-crab chitosan polyelectrolyte complex (PEC) bioplastic (A2) with magnification of 10.000x (a) and 3.000x (b)

discussion

Master’s thesis

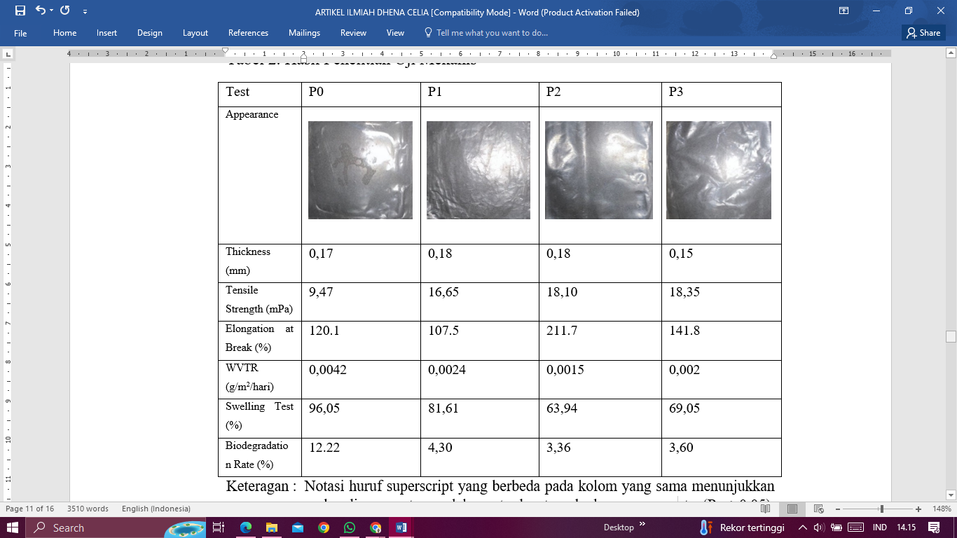

Bioplastic Polyelectrolyte Complex (PEC) from Kappa Carrageenan and Shrimp, Crab, and Fish Scale Chitosan as Food Packaging.

research background

result

Bioplastic offers an eco-friendly alternative to synthetic plastics and can be made from natural polysaccharides like κ-carrageenan, known for its gel-forming properties. However, the mechanical properties of κ-carrageenan bioplastics often fall below standard. Enhancing these properties can be achieved by adding chitosan, which forms polyelectrolyte complexes (PECs) with carrageenan through electrostatic interactions, eliminating the need for toxic crosslinking agents. The molecular weight of chitosan, influenced by its source and extraction process, is crucial in PEC formation.

objective

The findings indicated that crab chitosan-κ carrageenan PEC bioplastic exhibited optimal results with a thickness of 0.178 mm, tensile strength of 18.053 MPa, elongation at break at 211.73%, water resistance of 63.94%, Water Vapor Transmission (WVT) of 0,001456 g/m2/day, biodegradation rate of 3.358% over 7 days, and the lowest TPC in fish fillets after 24 h, increasing from 4.39 log CFU/g to 7.45 log CFU/g.

This study aims to identify the most suitable type of chitosan for food packaging bioplastics using polyelectrolyte complex (PEC) method.

Method

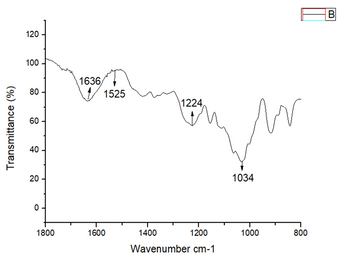

1034 cm-1

Aliphatic C–N stretching (amines)

1224 cm-1

Aromatic C–N stretching (amines)

Indicates the presence of sulfate groups from ammonium sulfate as a result of ionic interaction between the amine group of chitosan and the sulfate group of kappa carrageenan.

1525 cm-1

Primary amide bending (amides)

1636 cm-1

Primary amide bending (amides)

Indicates the presence of NH3+ which forms a polyelectrolyte complex with kappa carrageenan.

Three types of commercial chitosan with different molecular weights were evaluated (shrimp, crab, and fish scale chitosan). JIS were used for characterization assessment of bioplastics such as thickness, tensile strength, water resistance, water vapor transmission, and biodegradation rate as well as additional tests including FTIR, SEM analysis, and TPC on fish fillets.

conclusion

Based on these results, molecular weight of chitosan was shown to significantly influence the PEC bioplastics characteristics.

medium

environment and sustainability

contact me

ADDRESS

surabaya, indonesia

email

dhenachp@gmail.com